Sensors, Free Full-Text

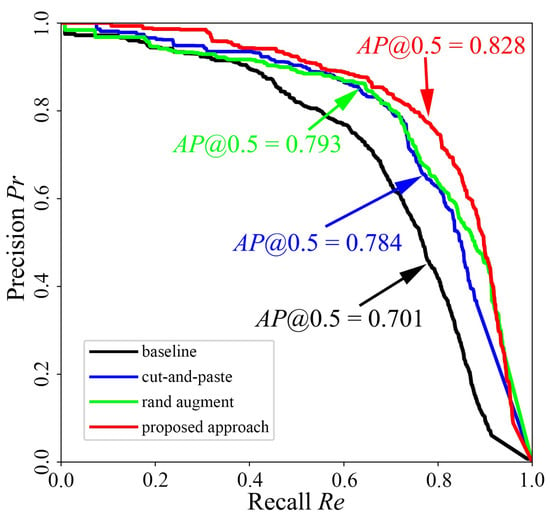

Surface defect detection and dimension measurement of automotive bevel gears by manual inspection are costly, inefficient, low speed and low accuracy. In order to solve these problems, a synthetic bevel gear quality inspection system based on multi-camera vision technology is developed. The system can detect surface defects and measure gear dimensions simultaneously. Three efficient algorithms named Neighborhood Average Difference (NAD), Circle Approximation Method (CAM) and Fast Rotation-Position (FRP) are proposed. The system can detect knock damage, cracks, scratches, dents, gibbosity or repeated cutting of the spline, etc. The smallest detectable defect is 0.4 mm × 0.4 mm and the precision of dimension measurement is about 40–50 μm. One inspection process takes no more than 1.3 s. Both precision and speed meet the requirements of real-time online inspection in bevel gear production.

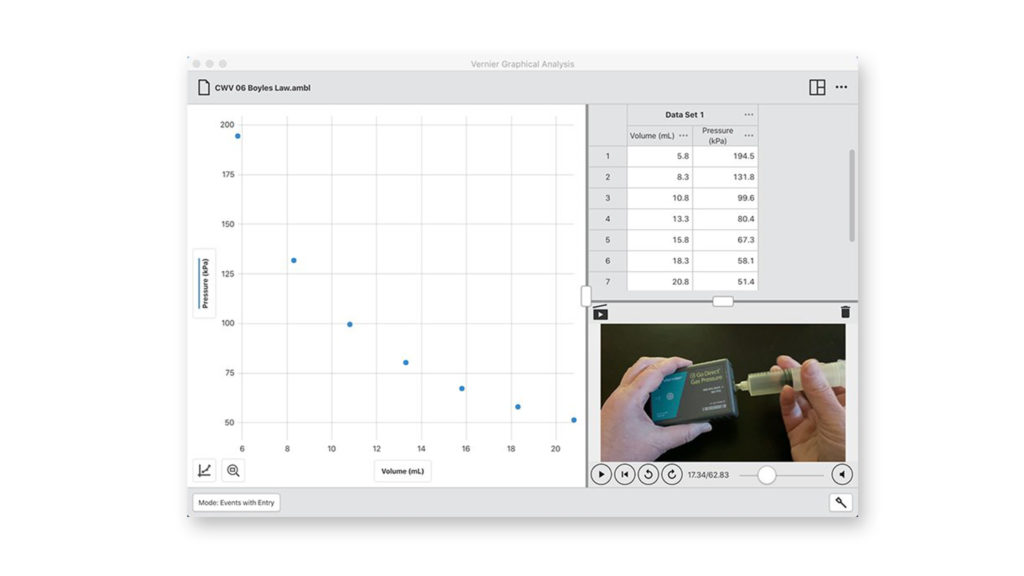

/wp-content/uploads/2020/09/boyles

Frontiers in Sensors

Architecture of Internet of Things (IoT) - GeeksforGeeks

Keyence LR-W500C RGB Full Spectrum Color Detection Sensor

Sensors, Free Full-Text, underground roleplay download

Sensors, Free Full-Text, thomas mitchell overton execution

Sensors, Free Full-Text, red engine spoofer

Sensors, Free Full-Text

PAPER SENSOR|PRODUCTS|KODENSHI CORP.

α9 III full-frame camera with a global shutter system

160+ ESP32 Projects, Tutorials and Guides with Arduino IDE